Casting Structure and Design

Technical Specifications

- Model No.: L018516

- Brand: Customizable (OEM/ODM supported)

- Material: High-grade Aluminum Alloy (Compliant with ASTM B85 standards for Aluminum die castings)

- Deck Configuration: Double Deck

- Net Weight: 603.52g (±2g tolerance for consistent production)

- Cavity Number: 2 (Optimized for high-volume manufacturing efficiency)

- Surface Finish: Spray Coating (Corrosion-resistant, scratch-proof; customizable finishes available)

- Production Machine: Cold Chamber Die Casting Machine (Ensures precise metal flow and solidification)

- Precision Tolerance: ±0.05mm for critical dimensions (Meets ISO 8062 Class CT6 standards)

- Maximum Operating Temperature: -40°C to 120°C (Stable performance in harsh environments)

- Mechanical Properties:

- Tensile Strength: ≥220 MPa

- Yield Strength: ≥160 MPa

- Elongation: ≥3% (At 50mm gauge length)

Product Images and Details

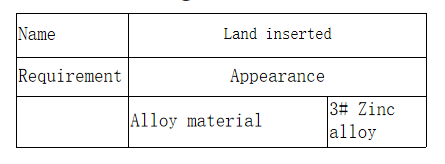

1. Casting Structure and Design

Figure 1: Detailed view of the Aluminum Die Casting structure (Model L018516), highlighting the double-deck layout, gating system, and cavity positions—critical for uniform metal flow during production.

2. Finished Casting Photographs

Figure 2: Finished Aluminum die casting (Model L018516) with spray coating surface finish. The image demonstrates the product’s smooth texture, absence of defects (e.g., blisters, scratches), and compliance with surface quality standards.

3. Casting Cross-Sectional Analysis

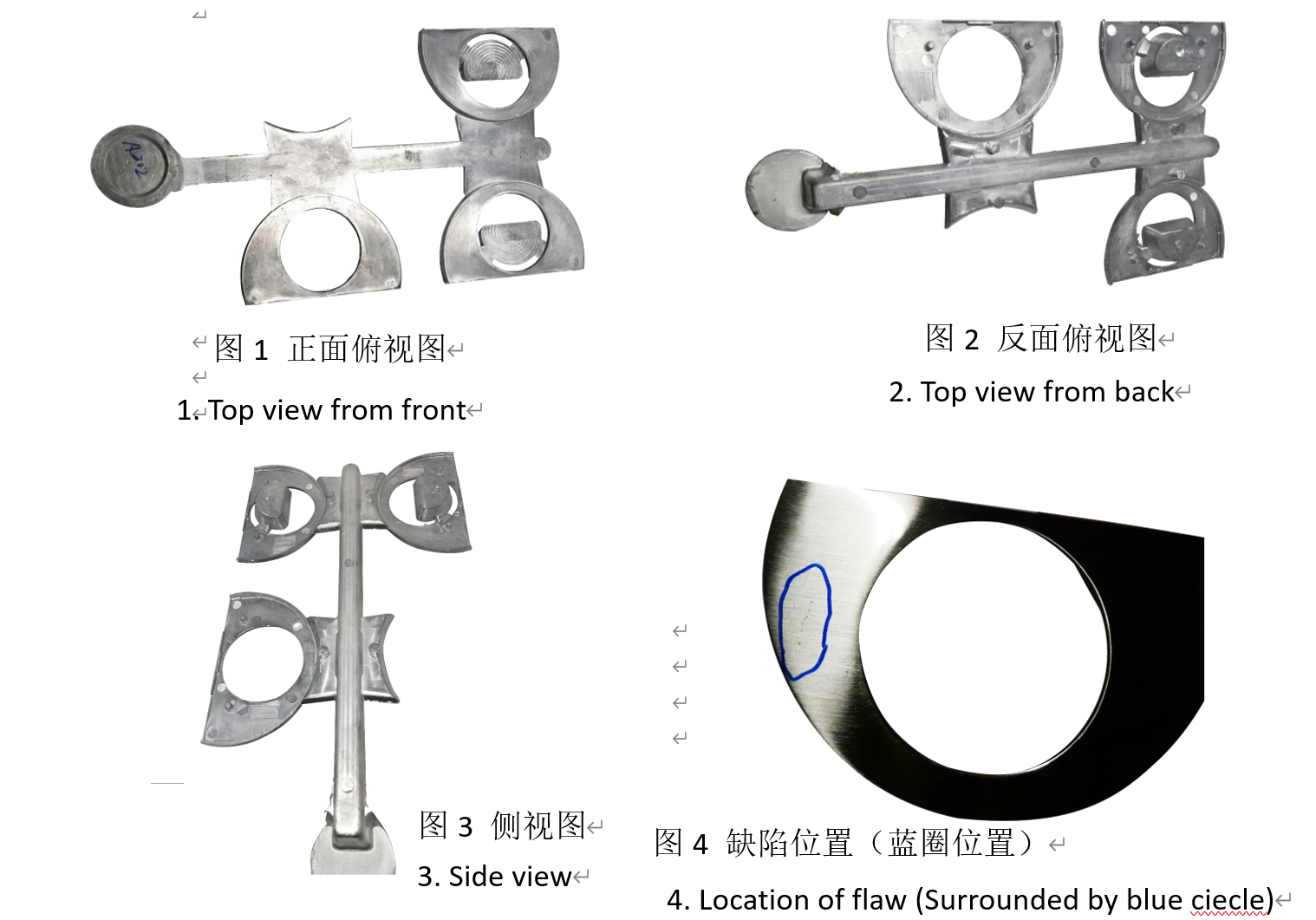

Figure 3: Cross-sectional view of the Aluminum casting (Model L018516), illustrating optimized internal structure, reduced porosity, and improved flow channel design—key to preventing electroplating blistering and gas entrapment.

4. Optimized Gating System Design

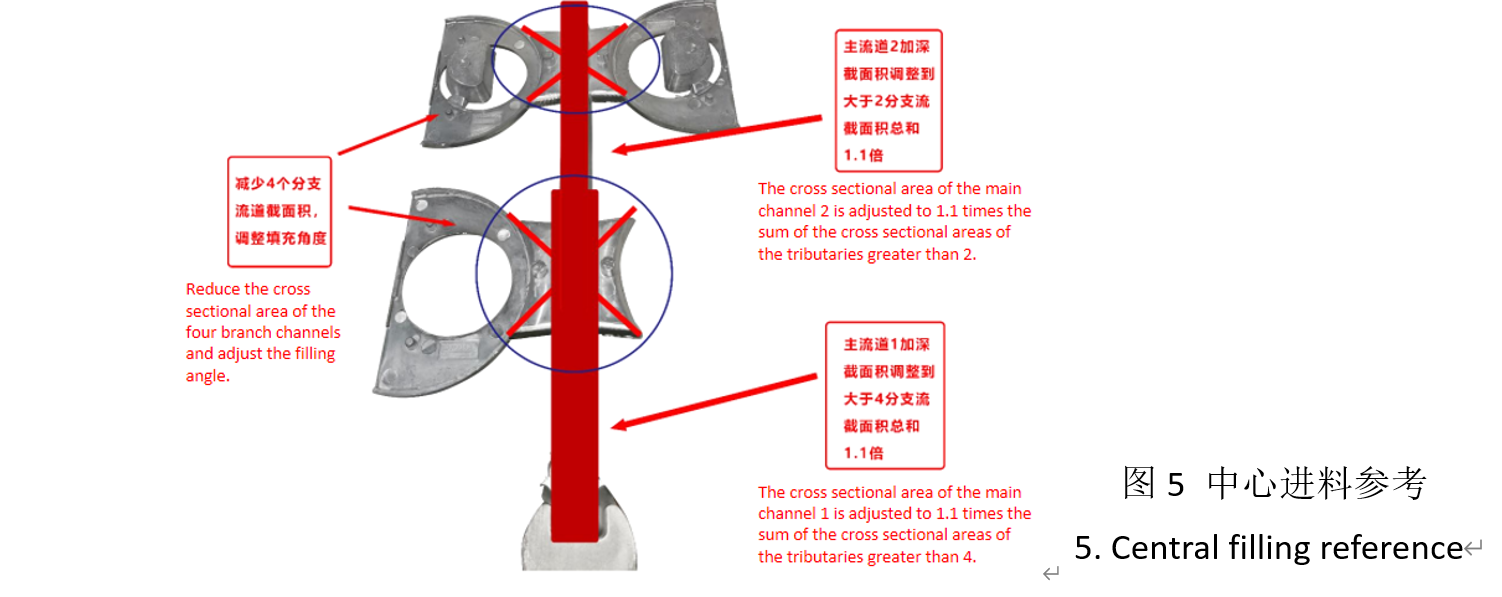

Figure 4: Improved gating system for the Aluminum die casting (Model L018516). The design includes an enlarged main channel (via deepening) and reduced branch channel cross-sections to minimize gas entrapment and ensure uniform metal filling.

Product Features and Advantages

1. Advanced Cold Chamber Die Casting Technology

Unlike standard die casting methods, our cold chamber machine ensures precise control over aluminum melting temperature (650-700°C) and injection speed. This technology eliminates common defects in Aluminum Castings, such as oxide skin formation and material temperature loss—issues that often lead to poor appearance and electroplating blistering. The result is a product with consistent mechanical properties and surface quality.

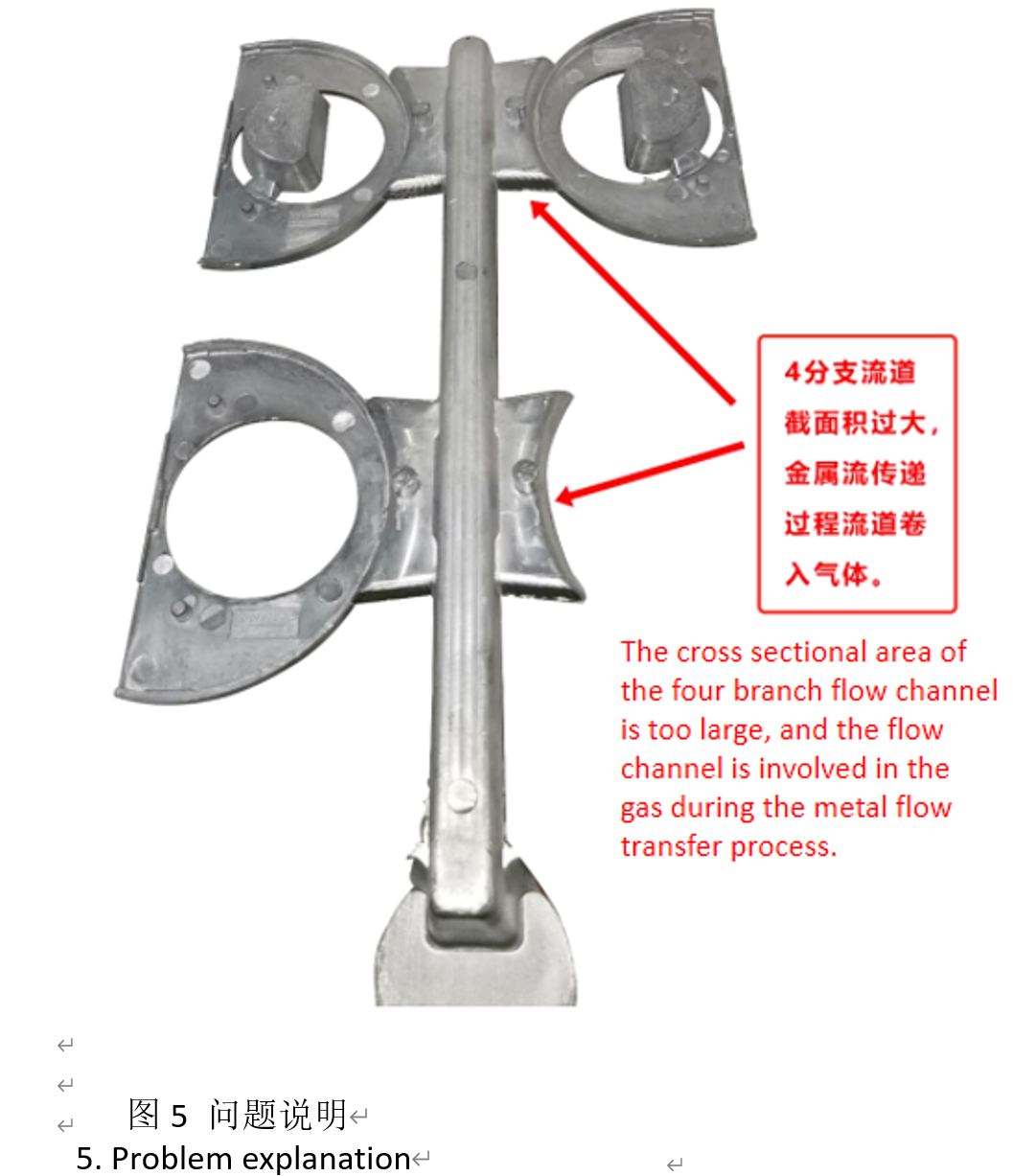

2. Optimized Gating System for Reduced Defects

Addressing a critical industry pain point, we’ve redesigned the gating system of Model L018516 to solve gas entrapment and uneven metal flow:

- Enlarged Main Channel: Due to space constraints, we deepened the main flow channel to increase its cross-sectional area (exceeding the sum of branch channels), ensuring smooth metal transfer and reducing gas absorption.

- Adjusted Branch Channels: Reduced the cross-sectional area of 4 branch channels and optimized filling angles to prevent turbulent flow—key to avoiding internal porosity and surface defects.

- Strategic Gate Placement: Following industry best practices, gates are positioned at the larger end of the casting section to minimize cavity air entrapment. For custom designs, we can reposition gates opposite current locations (as shown in Figure 4) for enhanced performance.

3. Temperature-Controlled Feeding System

To combat material temperature loss—a major cause of casting defects—we’ve integrated a custom oil-heated feeding pipe into the production process. This system maintains consistent aluminum temperature from melting to injection, ensuring optimal fluidity and reducing the risk of oxide skin formation. ForBuyer, this means fewer rejected parts and lower post-processing costs.

4. Double-Deck & 2-Cavity Design for Efficiency

The double-deck configuration and 2-cavity setup of Model L018516 maximize production efficiency:

- Double-deck design reduces machine footprint while increasing output per cycle.

- 2-cavity mold enables simultaneous production of two parts, cutting lead times by up to 30% for high-volume orders.

This efficiency translates to cost savings forBuyer without compromising on quality.

5. Durable Spray Coating Finish

The spray coating surface finish offers multiple benefits:

- Corrosion resistance: Protects the Aluminum die casting from harsh industrial environments (e.g., moisture, chemicals).

- Scratch resistance: Maintains aesthetic appeal and structural integrity during handling and assembly.

- Compatibility with post-processing: Can be easily painted or electroplated (if required) for custom applications.

Advantage Over Competitors

Compared to standard Aluminum die castings in the market, Model L018516 stands out in three key areas:

- Defect Rate: Our optimized processes reduce defects (e.g., blistering, porosity) to less than 1%, compared to the industry average of 5-8%.

- Production Speed: 2-cavity design and cold chamber technology enable 20% faster output than single-cavity alternatives.

- Customizability: We offer flexible adjustments to surface finish, cavity number, and dimensions—unlike rigid “one-size-fits-all” products from competitors.

How to Integrate and Handle the Aluminum Die Casting

Step 1: Pre-Installation Inspection

- Unpack the Aluminum die casting (Model L018516) and check for surface damage (e.g., scratches, dents) using visual inspection—refer to Figure 2 for quality benchmarks.

- Verify dimensional accuracy with calibrated tools (e.g., calipers, micrometers) to ensure compliance with your assembly requirements (tolerance: ±0.05mm).

- For electroplating or additional coating: Clean the surface with a mild alkaline solution to remove residual release agents—this prevents adhesion issues.

Step 2: Assembly Integration

- Position the double-deck casting in your assembly fixture, aligning with mounting holes (if applicable). Use non-abrasive clamps to avoid surface damage.

- For parts requiring fastening: Use aluminum-compatible screws (e.g., stainless steel) with torque settings of 2-3 N·m—over-tightening may cause deformation.

- If integrating with other components (e.g., electronic modules, mechanical parts), ensure clearance for thermal expansion (aluminum expands ~23.1 μm/m·°C).

Step 3: Post-Installation Quality Check

- Conduct a leak test (if used in fluid-handling applications) to ensure no porosity or cracks—our casting’s cross-sectional integrity (Figure 3) minimizes failure risk.

- Test mechanical performance (e.g., load-bearing capacity) within the product’s rated limits (tensile strength ≥220 MPa) to confirm durability.

Step 4: Maintenance Guidelines

- Clean the casting periodically with a dry cloth—avoid harsh solvents that may damage the spray coating.

- Store unused parts in a dry, temperature-controlled environment (15-25°C, relative humidity ≤60%) to prevent oxidation.

- For long-term use: Inspect the coating annually for wear—reapply spray coating if signs of corrosion appear.

Application Scenarios

Our Aluminum die casting (Model L018516) is versatile enough to serve multiple industries, thanks to its durability, precision, and customizable design. Below are key application areas whereBuyer have successfully integrated this product:

1. Automotive Industry

- Component Use: Double-deck castings for engine cooling systems (e.g., radiator brackets, coolant channels) and electronic control unit (ECU) enclosures.

- Why It Works: High temperature resistance (-40°C to 120°C) and corrosion resistance (spray coating) withstand under-hood conditions. The 2-cavity design enables mass production to meet automotive volume demands.

2. Electronic & Electrical Industry

- Component Use: Housings for industrial sensors, power inverters, and 5G base station modules.

- Why It Works: Aluminum’s excellent thermal conductivity (160 W/m·K) dissipates heat from electronic components, while the spray coating provides electrical insulation. The double-deck design saves space in compact devices.

3. Industrial Machinery

- Component Use: Structural parts for conveyor systems (e.g., roller brackets) and hydraulic valve bodies.

- Why It Works: High tensile strength (≥220 MPa) and low weight (603.52g) reduce machinery load while ensuring durability. The optimized gating system eliminates internal defects, preventing fluid leaks in hydraulic applications.

4. Medical Equipment

- Component Use: Frames for portable medical devices (e.g., ultrasound machines) and sterilization tray holders.

- Why It Works: Non-toxic aluminum material complies with medical industry standards (e.g., ISO 10993). The smooth spray coating is easy to clean and sterilize, reducing contamination risk.

Benefits for InternationalBuyer

- Cost Savings Through Efficiency: The 2-cavity mold and cold chamber technology reduce production time by 20-30%, lowering unit costs for high-volume orders (MOQ: 4000 pieces). Additionally, our optimized processes cut defect rates to <1%, minimizing scrap and rework expenses.

- Reliable Quality for Global Markets: Compliant with international standards (ASTM B85, ISO 8062), our Aluminum die castings meet the regulatory requirements of regions like the EU (CE), North America (ANSI), and Asia (JIS). This eliminates barriers to market entry forBuyer.

- Customization to Fit Unique Needs: We offer adjustments to surface finish (e.g., anodizing, powder coating), cavity number (1-4 cavities), and dimensions—ensuring the product aligns with your specific assembly or design requirements. No more compromising on “standard” parts.

- Reduced Lead Times: With a dedicated production line for Aluminum castings, we deliver orders in 4-6 weeks (for standard specs) and 8-10 weeks (for custom designs)—faster than the industry average of 8-12 weeks.

- Long-Term Durability: The combination of high-grade aluminum, spray coating, and defect-free production ensures the casting has a service life of 5+ years in industrial applications. This reduces maintenance costs and replacement frequency forBuyer.

- Transparent Supply Chain: We provide real-time production updates and quality reports (including cross-sectional analysis, as in Figure 3) throughout the order process—givingBuyer full visibility and peace of mind.

Certifications and Compliance

Our Aluminum die casting (Model L018516) and production processes adhere to strict international standards, ensuring quality and compliance for globalBuyer. Below are key certifications and compliance credentials:

- ISO 9001:2015: Quality management system certification, covering all stages from design to delivery—ensuring consistent product quality.

- ASTM B85-20: Standard specification for aluminum-alloy die castings, verifying material purity and mechanical properties.

- ISO 8062 Class CT6: Dimensional tolerance standard for die castings, confirming our ±0.05mm precision meets global requirements.

- RoHS Compliance: Free of hazardous substances (e.g., lead, mercury) to meet EU and global environmental regulations.

- CE Certification: Valid for sales in the European Economic Area (EEA), ensuring compliance with health, safety, and environmental protection standards.

- IATF 16949:2016 (Optional): For automotiveBuyer, we offer IATF-certified production processes—specifically tailored to automotive industry quality requirements.

We provide certification documents with every order, enablingBuyer to streamline their own regulatory approvals.

Customization Options

We understand that everyBuyer has unique needs. Beyond the standard Aluminum die casting (Model L018516), we offer flexible customization to align with your specific application, design, and branding requirements:

1. Material Customization

- Aluminum Alloy Grades: A380 (standard), A383 (higher strength), A413 (heat-resistant) — selected based on your application’s mechanical and thermal needs.

- Material Additives: Optional trace elements (e.g., magnesium, silicon) to enhance specific properties (e.g., corrosion resistance, machinability).

2. Design & Dimensional Customization

- Deck Configuration: Single or triple-deck designs (beyond the standard double-deck) to fit space constraints.

- Cavity Number: 1, 3, or 4 cavities (adjusted for production volume needs—1-cavity for prototypes, 4-cavity for maximum output).

- Dimensions: Custom length, width, and height (up to 500mm × 300mm × 200mm) with precision tolerances as tight as ±0.02mm for critical features.

- Mounting Features: Integrated holes, threads, or slots (drilled or tapped during production) to eliminate post-processing.

3. Surface Finish Customization

- Coating Types: Anodizing (clear, black, or colored), powder coating (textured or smooth), or electroplating (nickel, chrome) — ideal for aesthetic or functional needs (e.g., conductivity, corrosion resistance).

- Branding: Laser engraving of logos, part numbers, or QR codes (for traceability) on the casting surface.

4. Production Process Customization

- Quality Testing: Additional tests (e.g., X-ray inspection for internal defects, salt spray testing for corrosion resistance) beyond our standard quality control.

- Packaging: Custom packaging (e.g., anti-static bags, labeled cartons) to protect parts during shipping and align with your inventory systems.

Our engineering team provides free design-for-manufacturability (DFM) analysis for custom orders—ensuring your design is optimized for die casting, cost-effective, and high-quality.

Production Process & Quality Control

1. Production Flow for Aluminum Die Casting (Model L018516)

- Design & Mold Fabrication:

- Engineers use CAD software to finalize the casting design (including gating system, as shown in Figure 4) and conduct simulation tests to predict metal flow and defect risks.

- Mold fabrication: High-grade H13 steel is used to create the 2-cavity mold, with heat treatment to ensure durability (mold life: 500,000+ cycles).

- Material Preparation:

- Aluminum alloy ingots are melted in a furnace at 650-700°C, with degassing agents added to remove impurities (e.g., hydrogen) that cause porosity.

- The molten aluminum is transferred to the cold chamber machine via the custom oil-heated feeding pipe (to prevent temperature loss).

- Die Casting:

- The cold chamber machine injects molten aluminum into the mold at high pressure (80-120 MPa) and speed (2-5 m/s), ensuring full cavity filling.

- The mold is cooled with water channels to control solidification time—critical for dimensional accuracy.

- Trimming & Deburring:

- Automated trimmers remove excess material (e.g., sprue, runners) from the casting.

- Robotic deburring tools smooth edges to meet surface finish requirements (Ra ≤ 1.6 μm).

- Surface Treatment:

- The casting undergoes spray coating (standard) or custom finishes (e.g., anodizing) in a controlled environment to ensure uniform coverage.

- Coated parts are cured at 180-200°C for 30 minutes to enhance adhesion and durability.

- Final Inspection & Packaging:

- Parts are inspected for quality (dimensions, surface defects, mechanical properties) before being packaged in moisture-proof cartons.

2. Strict Quality Control Measures

- In-Process Inspection:

- Material temperature is monitored every 10 minutes to ensure it stays within 650-700°C.

- Every 50th casting is checked for dimensional accuracy using a CMM (Coordinate Measuring Machine) to verify compliance with ISO 8062 Class CT6.

- Post-Production Testing:

- Visual inspection: 100% of parts are checked for surface defects (e.g., blisters, scratches) against Figure 2’s quality standard.

- Mechanical testing: Random samples undergo tensile strength and elongation tests to confirm compliance with ASTM B85.

- Cross-sectional analysis: As shown in Figure 3, samples are cut and polished to check for internal porosity or cracks—reject rate for non-compliant parts is <1%.

- Traceability: Each batch is assigned a unique lot number, linking to production records (material source, machine parameters, inspection results) for 5 years—enabling easy recall if needed.

Customer Testimonials

“We’ve been using Model L018516 Aluminum die castings for our automotive radiator brackets for 2 years. The defect rate is less than 0.5%, which is way below our previous supplier’s 7%. The 2-cavity design also cut our lead time by 25%—critical for meeting our production deadlines.”

— Marco Rossi, Procurement Manager, AutoParts S.p.A. (Italy)

“As a manufacturer of medical devices, we need castings that meet strict quality and safety standards. This Aluminum casting’s RoHS compliance and smooth spray coating make it perfect for our ultrasound machine frames. The customization team also adjusted the mounting holes to fit our design—no extra machining needed.”

— Sarah Chen, Engineering Director, MedTech Innovations (USA)

“We ordered 10,000 units of Model L018516 for our industrial sensor housings. The thermal conductivity of the aluminum keeps our sensors cool, and the double-deck design saves space in our devices. The team provided real-time production updates, and the order arrived 1 week early—excellent service.”

— Kim Ji-hoon, Supply Chain Manager, TechSensor Co. (South Korea)

Frequently Asked Questions (FAQ)

Q1: What is the minimum order quantity (MOQ) for Model L018516?

A1: The standard MOQ is 4000 pieces. For prototype or small-batch orders (100-1000 pieces), please contact our sales team—we offer flexible terms for new customers or custom designs.

Q2: Can you provide samples before mass production?

A2: Yes. We can produce 5-10 sample pieces of the Aluminum die casting (Model L018516) within 2 weeks. Samples include full quality reports (dimensional tests, surface finish checks) to confirm compliance with your requirements. Sample costs are refundable if you place a mass production order of ≥4000 pieces.

Q3: What is the lead time for standard and custom orders?

A3: For standard Model L018516 (spray coating, 2-cavity), lead time is 4-6 weeks. For custom orders (e.g., different alloy, surface finish, or cavity number), lead time is 8-10 weeks (includes mold adjustment and testing).

Q4: Do you offer testing reports for the aluminum die castings?

A4: Yes. Every order includes a detailed quality report with:

- Dimensional inspection results (CMM data).

- Mechanical property test results (tensile strength, elongation).

- Surface finish analysis (Ra value).

- Certification copies (ISO 9001, ASTM B85, RoHS).

Additional tests (e.g., X-ray, salt spray) are available upon request for an extra fee.

Q5: What payment terms and incoterms do you accept?

A5:

- Payment Type: T/T (Telegraphic Transfer) — 30% deposit upon order confirmation, 70% balance before shipment.

- Incoterms: FOB, CFR, CIF, FCA ( Ningbo or Shanghai ports).

- For long-term customers, we offer flexible payment terms (e.g., 50% deposit, 50% balance after delivery).

Q6: How do you handle damaged or defective parts?

A6: We take full responsibility for any parts that do not meet the agreed quality standards. If you receive damaged or defective Aluminum castings:

- Notify us within 7 days of receiving the order, with photos and a detailed description of the issue.

- We will arrange for a replacement shipment (free of charge) or issue a refund—whichever you prefer.

- For critical orders, we can expedite replacements to minimize your production downtime.

Our defect rate is <1%, so this issue is rare—but we have a clear process to resolve it quickly.

Q7: Can you support OEM/ODM projects beyond Model L018516?

A7: Absolutely. We specialize in custom Aluminum die castings for OEM/ODM projects. Our engineering team will work with you to design castings that meet your exact specifications (material, dimensions, finish). We also offer mold design and fabrication services for unique designs—contact us with your CAD files or concept, and we’ll provide a free DFM analysis and quote.

Order & Shipping Information

1. Order Process

- Submit your inquiry: Provide details (quantity, specifications, customization needs) via email or our website form.

- Quote & sample: We send a detailed quote within 2 business days. If needed, we produce samples (2-week lead time) for your approval.

- Order confirmation: Once you approve the sample and quote, we issue a proforma invoice. You pay the 30% deposit to start production.

- Production & inspection: We update you on production progress weekly. Before shipment, we send a quality report for your review.

- Shipment: After you pay the 70% balance, we arrange shipping via your preferred method (ocean, land, air) from Ningbo or Shanghai port.

2. Shipping Details

- Transportation Options: Ocean (most cost-effective for large orders), Land (for regional orders in Asia/Europe), Air (expedited shipping for urgent orders).

- Export Ports: Ningbo, Shanghai (major Chinese ports with global connectivity).

- Shipping Time:

- Ocean: 20-30 days to Europe/USA, 7-14 days to Southeast Asia.

- Air: 3-5 days to most global destinations.

- Land: 5-10 days to neighboring countries (e.g., Vietnam, Thailand).

- Packaging: Standard packaging is moisture-proof cartons (20 pieces per carton, gross weight ≤20kg). Custom packaging (e.g., pallets, anti-static bags) is available upon request.

3. Contact Us for Orders

To place an order or inquire about our Aluminum die casting (Model L018516) or custom Aluminum castings, please contact our sales team:

- Email: sam@bldiecasting.com

- Phone: +86-18157495020

- Website: https://www.bldiecasting.com/ (submit inquiry via the “Contact Us” form)

Our team speaks English, Spanish, and German—we’re available 24/7 to answer your questions and support your procurement needs.